PRODUCT CATEGORIES

CONTACT US

DANBACH ROBOT JIANGXI.INC. Phone:+86-18602162995Tel:+86-0791-88133135

Fax:+86-0791-88221576

E-mail:info@dbhrobot.com

Address:No.811,Chuangxin 3rd road,High-tech district,Nanchang city,Jiangxi province,China

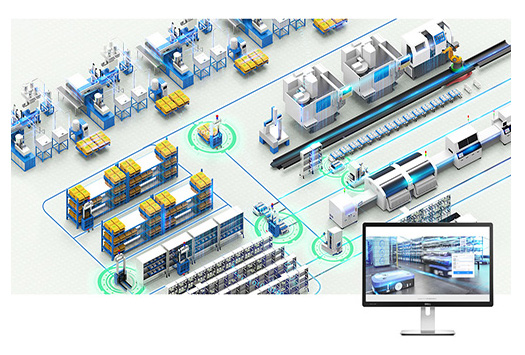

Digital Factory, smart and intelligent manufacturing plant

DANBACH ROBOT

With the development of a new round of industrial revolution, the voice of industrial transformation is growing. The face of information technology and industrial technology innovation wave, the Germans put forward the industrial 4.0 strategy, the Americans introduced the advanced manufacturing return program, China stepped up the two deep integration, and this year released the 2025 strategy of manufacturing in China. The core of these strategies is the use of new information technology to enhance the level of intelligent industrial applications, thereby enhancing the competitiveness of industry in the global market. As early as before the release of these strategies, including the concept of digital factories, intelligent factories and intelligent manufacturing has long been known to the industry. But can not be ignored, often many companies in the mention of these concepts, easy to confuse these concepts, digital factories, intelligent factories and intelligent manufacturing in the end whether the replacement of each other, these concepts are different? This article will analyze and explore this issue.

First, the digital factory

For the digital plant, the German Society of Engineers is defined as: The Digital Plant (DF) is a comprehensive network of digital models, methods and tools that includes simulation and 3D / virtual reality visualization integrated through continuous, uninterrupted data management. The digital plant integrates product, process and plant model databases with advanced visualization, simulation and document management to improve product quality and quality and dynamic performance involved in the production process.

In the country, the highest acceptance for the digital factory is defined as: digital factory in the computer virtual environment, the entire production process simulation, evaluation and optimization, and further extended to the entire product life cycle of the new production organization. Is a modern digital manufacturing technology and computer simulation technology products, mainly as a communication product design and product manufacturing bridge. From the definition can be drawn a conclusion, the essence of digital factory is to achieve the integration of information.

Second, the smart factory

Intelligent factory is based on the digital factory, the use of Internet technology and monitoring technology to strengthen information management services, improve the controllability of the production process, reduce the production line of human intervention, and reasonable planning and scheduling. At the same time, set the initial intelligent means and intelligent systems and other emerging technologies in one, to build efficient, energy saving, green, environmentally friendly and comfortable human plant.

Intelligent factory already has independent ability, can collect, analyze, judge, plan; Through the whole visual technology to carry on reasoning and forecasting, use simulation and multimedia technology, the realm expands the display design and manufacturing process. The system components can be composed of the best system structure, with coordination, reorganization and expansion features. The system has a self-learning, self-maintenance capabilities. Therefore, the intelligent factory to achieve the coordination of human and machine cooperation, its essence is human-computer interaction.

Third, intelligent manufacturing

Intelligent factory is based on the upgraded version of the digital factory, but there is a big gap with the intelligent manufacturing. Intelligent manufacturing system in the manufacturing process can carry out intelligent activities, such as analysis, reasoning, judgments, ideas and decision-making. Through the cooperation of human and intelligent machines, to expand, extend and partially replace the technical experts in the manufacturing process of mental work. It extends manufacturing automation to flexible, intelligent and highly integrated.

Intelligent manufacturing system is not only "artificial intelligence system, but the integration of intelligent systems, is a hybrid intelligence system can independently assume the analysis, judgments, decision-making and other tasks, highlighting people in the manufacturing system, the core position, while intelligent machine with , The better to play the human potential machine intelligence and human intelligence really integrated together, complement each other, complement each other is the essence of man-machine integration.

Many companies are still in the stage of the use of application software, a few companies only realize the information integration, that is, can reach the level of digital factory; very few companies that can achieve human-computer Of the effective interaction, that is, to the level of intelligent factories.

Previous:What factors determine the flexibility of industrial robots?

next:Danba analyzed from five industrial robot control system