PRODUCT CATEGORIES

CONTACT US

DANBACH ROBOT JIANGXI.INC. Phone:+86-18602162995Tel:+86-0791-88133135

Fax:+86-0791-88221576

E-mail:info@dbhrobot.com

Address:No.811,Chuangxin 3rd road,High-tech district,Nanchang city,Jiangxi province,China

Inertial navigation the AGV

DANBACH ROBOT

Introduction to inertial navigation AGV

Inertial navigation AGV products, is a combination of high-precision gyroscopes and encoders as a navigation device to vehicle electronic map as a new generation of positioning and path planning intelligent AGV products. Relative to the magnetic navigation AGV products, inertial navigation AGV products for the trackless navigation AGV products, can not be driven by a fixed route, with greater freedom of movement, particularly suitable for intelligent warehousing logistics, shop assembly and other mobile applications, especially for more AGV work in parallel.

Product Advantages of Inertial Navigation AGV of

2, the use of vehicle electronic map positioning method, AGV can move all-round, full freedom to move.

3, a higher degree of intelligence, you can automatically avoid, congestion control more flexible.

4, the real AGVS products, and ERP, WMS software interface to complete the dynamic path generation and task automatically assigned function.

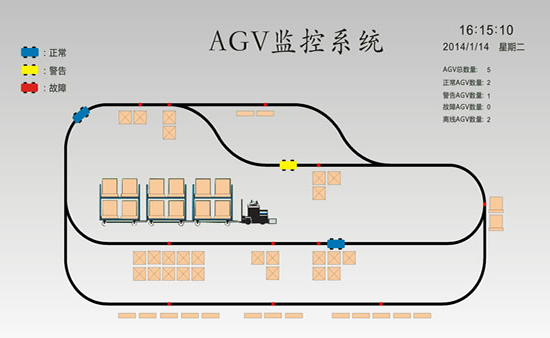

5, powerful traffic control software support, support map editing, task scheduling, dynamic call and task real-time monitoring, reporting statistics and more.

6, supports a variety of application scenarios, can support transfer, lifting, forklifts and other types of body.

Inertial navigation AGV is suitable for the following cases

2, multi-AGV collaborative task, the path laying complex, or the distance is too long;

3, the space is narrow, you need AGV forward, backward or lateral movement;

4, the other is not convenient to lay the application of magnetic stripe.

Inertial navigation AGV specification parameters

| product name | Latent traction | Latent lift | Carry the load |

| Body dimensions | custom made | ||

| Load form | Latent traction | Latent lift | Carry the load |

| load capacity | 0-1500 kg | 0-1000 kg | 0-1500 kg |

| speed | 0-60m / min (speed can automatically switch) | ||

| Guidance accuracy | ± 10 mm | ||

| Parking accuracy | ± 10 mm | ||

| Gradeability | ≤3% | ||

| AGV control mode | automatic / manual | ||

| AGV navigation mode | Inertial navigation | ||

| AGV drive mode | Steering gear | ||

| AGV walking way | Forward, backward, turn left and right, | ||

| Wireless communication | Internal LAN (wifi) | ||

| Safety guards | Walking contact bumper + laser non-contact collision avoidance sensor + sound and light alarm + system dynamic monitoring | ||

| Electrical wiring | In accordance with the electrical installation standards and user requirements | ||

| Power display | Touch screen with battery power indicator, when the battery is low alarm | ||

| Driving route | When multiple routes cross, you can follow the required route | ||

| Use of the environment | The AGV vehicle satisfies the production environment conditions of the consumer plant | ||

| Quality and Safety | AGV car composite state-related quality standards, environmental standards, electrical safety standards | ||

| Normal turning radius | > 1000 mm | ||

| Battery | Lithium Battery / Lead Acid Battery (24V) | ||

| Charging method | Automatic charging or manual charging | ||

Previous:Laser-guided forklift the AGV

next:AGV car control system