PRODUCT CATEGORIES

CONTACT US

DANBACH ROBOT JIANGXI.INC. Phone:+86-18602162995Tel:+86-0791-88133135

Fax:+86-0791-88221576

E-mail:info@dbhrobot.com

Address:No.811,Chuangxin 3rd road,High-tech district,Nanchang city,Jiangxi province,China

Connotation intelligent manufacturing technology and key tec

DANBACH ROBOT

"Made in China 2025" since the launch last year, the state's largest investment, support is the largest intelligent manufacturing. Smart Manufacturing (Smart Manufacturing) is to achieve the entire manufacturing value chain of intelligence and innovation, information technology and industrialization of the further integration of the further enhance the depth. Intelligent manufacturing from a single software to small fusion, and then to the continuous integration of today into the depth of integration of the times. Intelligent manufacturing combines information technology, advanced manufacturing technology, automation technology and artificial intelligence technology.

However, intelligent manufacturing is still at the level of "Smart". The intelligent manufacturing system has the ability of data acquisition, data processing and data analysis. It can execute the instruction accurately and realize closed-loop feedback. The trend of intelligent manufacturing is to realize " Intelligent Manufacturing System, which can realize autonomous learning, make decisions independently and continuously optimize itself.

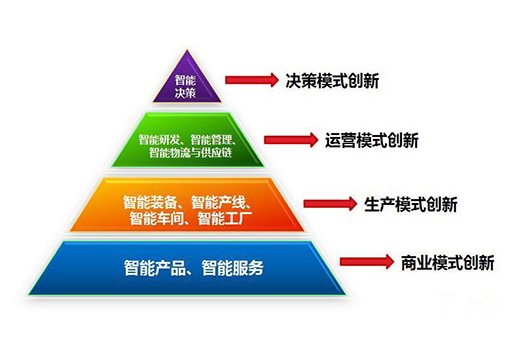

Intelligent manufacturing technology can be a four-story pyramid. The bottom is the foundation of the enterprise, intelligent products and intelligent services, which are related, can bring us business model innovation. There are already many business model innovation around these two aspects, especially in the equipment manufacturing industry, intelligent services have a very large imagination. The second level is intelligent equipment, intelligent production lines, intelligent workshops and intelligent factories, bringing the production mode of innovation. The third level is intelligent management, intelligent R & D, intelligent logistics and supply chain, bringing the business model of innovation. The top floor is an intelligent decision making model that brings innovation.

Intelligent manufacturing also requires a lot of intelligent technology to make it possible, without these things, the above things can not be achieved. These technologies include networking, robotics, material manufacturing, cloud computing, large data analysis, electronic data interchange, and augmented reality. In the intelligent manufacturing technology pyramid, the intelligent manufacturing of the ten key technologies are:

1, intelligent products

Changan Automobile unmanned vehicle development, in April this year, opened directly from Chongqing to Beijing auto show. The following figure is a street in San Francisco to see a smart trash, the trash set of solar energy, Internet of things, efficient compressor as a whole, when the garbage is full, the compressor will be 40 seconds to reduce the volume of garbage to the original five One, the trash can be automatically connected when the network is full, send trash is full and geographical location and other information to the garbage disposal center. The processing center of the system according to the data sent back to each trash analysis, planning the best recovery routes and time. The product also provides WIFI hotspots.

Previously staff will see the full day, and now full of their own call, this is the smart. So we should also develop such a product in China, such a trash can sell tens of thousands of pieces, all cities in the United States are deployed.

2, intelligent services

Intelligent Services Based on sensors and Internet of Things (IoT), you can sense the status of your products for preventive maintenance, help customers to replace spare parts in a timely manner, and even help customers get business opportunities by understanding the status of product operations. Through the collection of product operations of large data, to assist enterprises in marketing decisions. Through the development of customer service-oriented APP, you can purchase products for the enterprise to provide targeted services, and thus lock the user.

Recently there is a very interesting phenomenon. For example, one of the leading global PLM companies, the United States PTC company invested heavily in the Internet of Things and service life cycle management, to become one of the leading enterprises in the field of intelligent services. For example, Rolls-Royce's Total Care service, which now sells performance-based payments, is consistent with its position and customer position.

We all hope that the quality of products is the best, used to be good enough, you really have the ability to provide performance-based pay, of course, have enough confidence in the product. Recently we went to visit a company in Shandong, the shield is paid by the meter, because the shield is a complex structure of the hard rock, different materials have to have a different knife to cut, otherwise the effect is different.

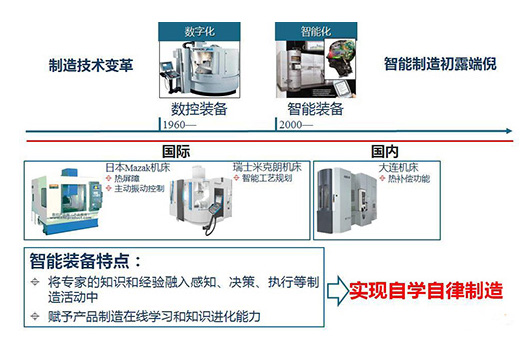

3, intelligent equipment

There are many types of intelligent manufacturing equipment, including industrial robots. But not all industrial robots are called intelligent robots, it should be clear. For example, the figure is the Huazhong University of Science and Technology Li Dequn development of intelligent CNC injection molding machine, the traditional injection molding machine, injection molding machine intelligent expert system software, Process automatic monitoring and fault diagnosis and other functions.

As well as some of the latest German equipment, to a certain extent, also reflects the characteristics of intelligent equipment. Laser cutting machines are usually cut flat, and the fast group of high-speed laser processing is the CNC machining, coordinate / 5-axis machining center and laser cutting together. Not only to provide the cutting machine itself, but also provide automated equipment, also provides related software, and more than one laser cutting machine can share a light source. TRUMPF offers this service through European third-party industrial cloud platforms.

In addition, when we are talking about the integration of materials manufacturing and traditional manufacturing integration, DMG provided LASERTEC 65 equipment, laser welding method instead of casting, and then use the milling cutter and the material technology for deep processing, this processing Process can not only manufacture new products, but also on the old products for maintenance.

GE has set up a huge production center in Pittsburgh, with more than 100 manufacturing facilities. The United States UPS said the future will become the world's largest manufacturer of materials, and you order a shoe design style to it that print on it. There will be such a cross-border integration.

Let us look at what is intelligent robots? Last year at Hanover, ABB's Yumi collaboration robot did not need to avoid human activities. Reclaiming the time, all parts are randomly placed, it has a machine identification function, you can accurately get all the parts needed.

Recently, Dr. Germany has also introduced a similar robot, that the future of the robot is not a substitute, but man-machine collaboration.

4, intelligent production line

Intelligent production line, in the production and assembly process, through the sensor or RFID technology for automatic data collection, and real-time display of production status through the electronic billboards; Through the machine vision and a variety of sensors for quality testing, automatically reject unqualified products, And SPC analysis of the collected quality data to identify the causes of quality problems; to support a variety of similar products mixed line production and assembly, flexible adjustment process to adapt to small quantities, multi-species production mode; flexible, if the production line Equipment failure, can be adjusted to other equipment production; for manual operation of the station, to give intelligent tips.

Previous:Manufacturing Sharing Economy Research and Practice

next:none