PRODUCT CATEGORIES

CONTACT US

DANBACH ROBOT JIANGXI.INC. Phone:+86-18602162995Tel:+86-0791-88133135

Fax:+86-0791-88221576

E-mail:info@dbhrobot.com

Address:No.811,Chuangxin 3rd road,High-tech district,Nanchang city,Jiangxi province,China

Manufacturing Sharing Economy Research and Practice

DANBACH ROBOT

September 2, 2016, the first "Industrial Software and Manufacturing Convergence Summit" was held in Beijing, e-works digital enterprise network editor-in-chief Dr. Huang Pei published entitled "manufacturing sharing of economic exploration and practice" speech Report, according to the contents of this lecture from finishing.

Dr. Huang Pei, editor-in-chief of e-works Digital Enterprise Network

At present, with the supply side of the reform, as well as to the production capacity and adjust the structure of a two-pronged approach, many manufacturers began to face orders, operating rate and other issues. Recently visited a textile machinery business learned that the enterprise income of 400 million the year before last year, has fallen to 2 million. There is a heavy industry, the peak income of more than 500 billion, and so far this year is less than 10 billion, showing a cliff-type decline. This has led to a lot of manufacturing enterprises in the production equipment and testing equipment in the idle state, equipment utilization is very low, and many local equipment matching rate is not high, leading to a large number of orders outflow to the coastal areas. Large enterprises complained about the low rate of mold matching, small and medium enterprises lack of technology and manufacturing resources; enterprise product light service, lack of awareness of manufacturing services; have the resources of the enterprises guarding Jinshan no food, there is a demand for enterprises but can not find matching and Association of manufacturers. These have become common problems in the process of China's manufacturing industry transformation.

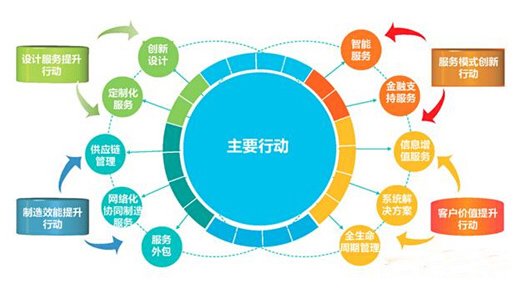

In response to these common problems have emerged, the Ministry of Industry in July this year issued a "development of service-oriented manufacturing special action guide", proposed design services to enhance the action, manufacturing performance improvement action, service innovation and customer value action action. Its purpose is to guide the integration of manufacturing and service development, speed up the manufacturing industry from production to service-oriented transformation. Through innovation and optimization of production organization form, operation management and business development model, increasing service elements in the input and output in the proportion of processing and assembly in order to achieve the main "manufacturing + service" transformation, from the simple sale of products to sell " Product + service "transformation, is conducive to extend and enhance the value chain, improve the total factor productivity, product value-added and market share.

First, share the economy to bring new market opportunities

The so-called sharing of the economy refers to the social mass, scattered, idle resources, platform-based, collaborative clustering, reuse and supply and demand match, in order to achieve economic and social value of the new form of innovation. Sharing the economic emphasis on the two core concepts is the "use without possession" and "do not use or waste." At present, the most typical share of the economy is the traffic travel and life services. Such as dropping a ride is a way to share the economy, the community to use the excess travel resources, the formation of a resource will be limited to fully utilize the sharing of economic industries.

In addition, there are office space rental, tourism short rent, education, training and other types of consumption links to share the economy. Why are these here collectively referred to as consumer links to share the economy? Because then I have to talk about is different from the consumer part of the production process to share the economy, that is, production equipment rental and outsourcing production mode-based production services. This model is conducive to promoting the integration of manufacturing and the Internet in order to take full advantage of the idle resources of manufacturing enterprises, to maximize the use of industrial equipment resources to promote the manufacturing industry from production to production services transformation.

Just the Ministry of Industry and the Secretary-General An Xiaopeng also talked about, to share the economy from the consumer links to the production process, to rent on behalf of the purchase, on-time billing is the sharing of production processes, such a way to solve business, especially small Enterprise development process in the face of many problems. SMEs can use a lower cost to use some high-quality manufacturing resources for the steady development of enterprises to provide a support.

Previous:none

next:Connotation intelligent manufacturing technology and key tec