PRODUCT CATEGORIES

CONTACT US

DANBACH ROBOT JIANGXI.INC. Phone:0086-18801818975Tel:0086-0791-88133135

Fax:0086-0791-88221576

E-mail:info@dbhrobot.com

Address:Nanchang High - tech Zone Innovation No. 811

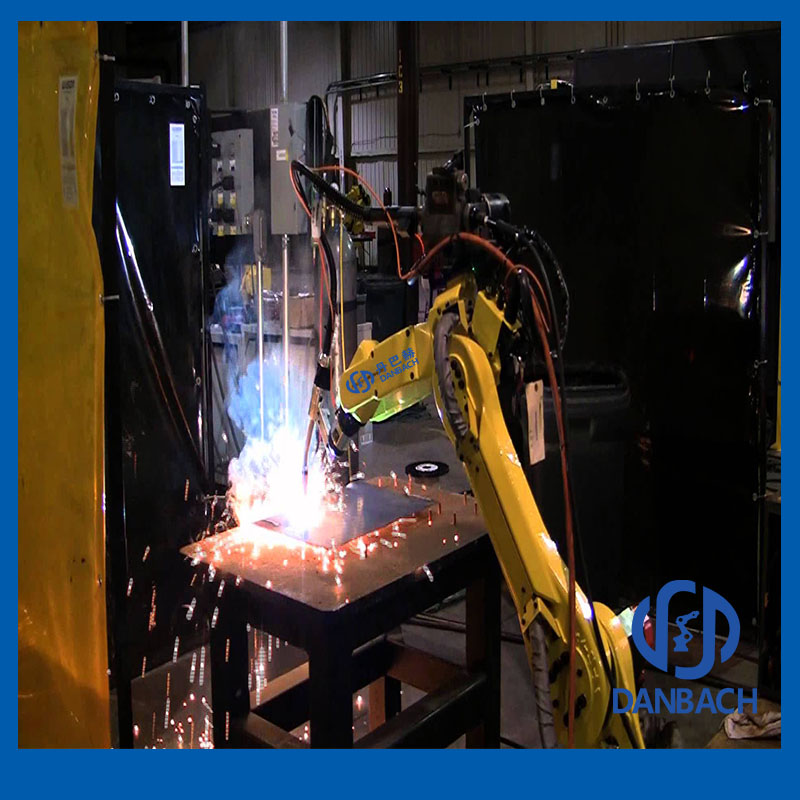

Using robotic automation to improve the efficiency of the welding process

DANBACH ROBOT

Robot-based automation can increase the efficiency of the welding process and enable your company to produce more products in a short period of time. It can also reduce the rate of defective products, improve quality, and improve the working environment.

Danbach robots can meet the needs of a wide range of users, such as the grabbing, mounting, assembly, grinding, and machining of bulk parts, through a wide range of functions and core components. Load: 8KG Dynamic Range: 727mm, Application: Handling, Pickup/Packaging.

The productivity of welding robots has been greatly improved:

1. Synthetic speed is improved by about 30% compared with the original organic type to achieve a reduction in takt time;

2. Adopt a design that reduces the interference between the arm and the surrounding equipment;

3, large load can achieve multiple areas of handling.

Danbach is one of the best suppliers of welding robots and complete welding kits. Buying all equipment and software from the same supplier simplifies the ordering process and shortens the delivery time. The automation of the robot improves the efficiency of the welding process. Not only that, because all the originals are designed and tested for seamless integration, their good collaboration is also very trustworthy.

Regardless of your welding process, arc welding, spot welding or laser welding, Danbach can provide the right solution for your needs.

Previous:Steering and Drive System of AGV Handling Robot

next:How to integrate industrial robots with CNC machine tools?