PRODUCT CATEGORIES

CONTACT US

DANBACH ROBOT JIANGXI.INC. Phone:0086-18801818975Tel:0086-0791-88133135

Fax:0086-0791-88221576

E-mail:info@dbhrobot.com

Address:Nanchang High - tech Zone Innovation No. 811

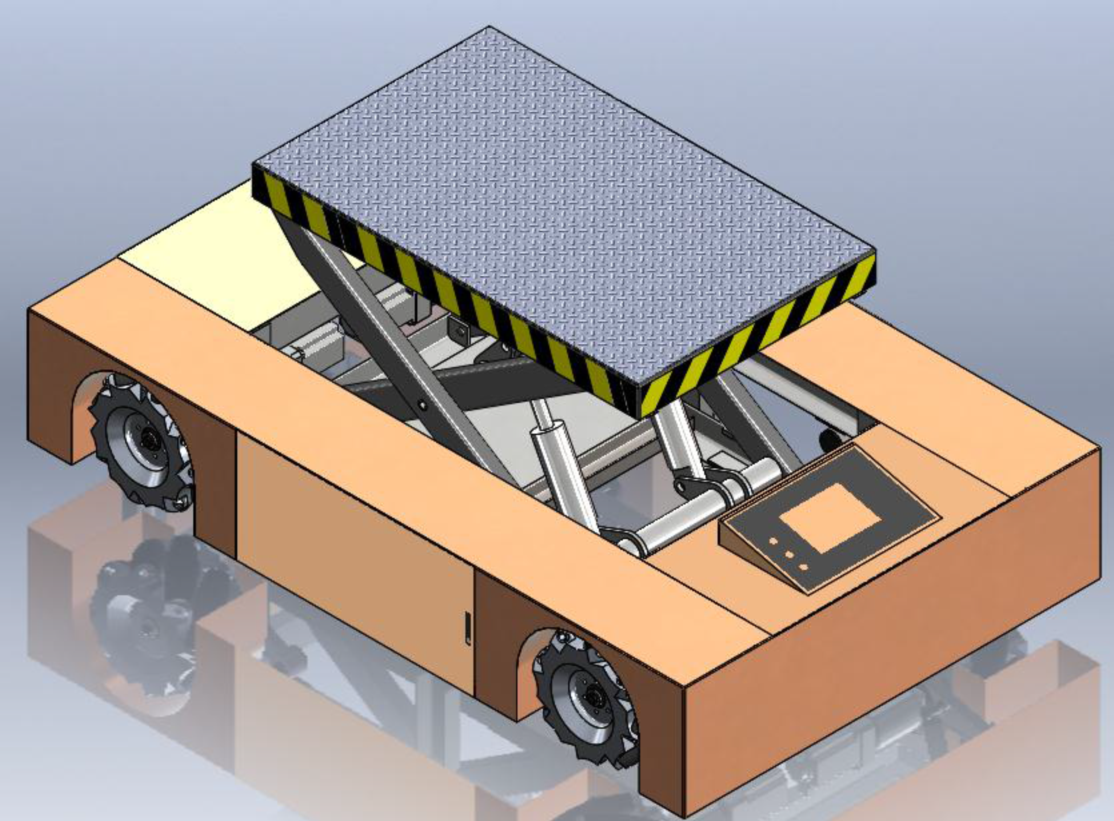

Intelligent manufacturing plant uses AGV trolley

DANBACH ROBOT

The market puts high demands on industrial automation production, and building an energy-efficient factory will become a major trend. High-automation intelligent equipment has also been favored by major factories, the development of artificial intelligence technology, and the country's strong support. So why are smart manufacturing plants willing to use AGV cars?

1, the cost is lower

With the development and maturity of domestic AGV technology, the cost performance of AGV is getting higher and higher, the demographic dividend is decreasing, and the rising labor cost has become a fact. Compared with the two, the advantages of the transformation and upgrading of the less-popular and unmanned chemical plants are increasingly obvious.

2, high security

In order to ensure the safety of the AGV during operation, the safety of field personnel and various types of equipment, AGV adopts multi-level hardware and software security measures.

3, high work efficiency

For example, in some industries, AGV is used to realize loading and unloading and back-and-forth transportation work, implementing non-stop refueling, shortening manual refueling time, planning the use of materials, avoiding various factors generated by the original refueling, and ensuring the smoothness of the assembly line. The AGV trolley can realize automatic charging function, which can achieve continuous operation for 24 hours, greatly improving work efficiency.

4, high reliability

Compared with the low efficiency of manual handling, the unknown path of forklift and trailer travel, speed and safety, the AGV's driving path and speed are controllable, and the positioning and parking are accurate, thus greatly improving the efficiency of material handling. At the same time, the AGV central management system The AGV trolley can be monitored throughout the entire process and the reliability is greatly improved.

5, save management energy

For example, a factory has more than 10,000 first-line operators, usually with high labor intensity, low income, different personal belongings, high employee fluctuations, and high turnover rate, which brings greater difficulty to enterprise management. The AGV robot is fully intelligently managed to improve the level of intelligent management and effectively avoid personnel factors.

6, better flexibility and system expansion

The AGV central management system can change the driving route of the AGV trolley to the maximum extent, and can control the traffic of the AGV running route after assigning the trolley task, which has better flexibility. At the same time, the AGV system has become part of the process flow and can be used as a link between many process connections, so it has high scalability.

Previous:Advantages of AGV trolley mobile assembly platform

next:The Application of Logistics Sorting Center AGV