PRODUCT CATEGORIES

CONTACT US

DANBACH ROBOT JIANGXI.INC. Phone:0086-18801818975Tel:0086-0791-88133135

Fax:0086-0791-88221576

E-mail:info@dbhrobot.com

Address:Nanchang High - tech Zone Innovation No. 811

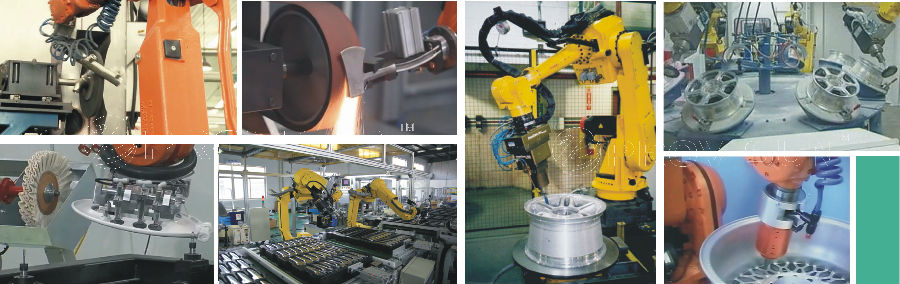

Integration of Industrial Robots and CNC Machines

DANBACH ROBOT

In the field of numerically-controlled machine tool processing applications, the integration of local machine tool loading and unloading robots and numerical control machine tools has been developed at the forefront. From the industrial application level, there have also been major changes:

1. Work Island: Single-to-single-unit motivation plus single-to-many online processing.

2. Flexible Manufacturing System (FMS): Based on the network-controlled flexible machine line addition, the PLC control platform is used, and multiple industrial robots, multiple CNC machine tools and their auxiliary equipments are connected in a group line by means of an industrial Ethernet bus. Beats for orderly automatic production.

3. Digital workshop: With CAD CAM CAPP assisted production tools, logistics technology and sensor technology, it has the functions of production process monitoring, real-time feedback of online faults, processing process data management, tool information management, equipment maintenance data management, product information records and other functions , to meet the needs of unmanned processing, to achieve the production system of the processing system, operation, coordination and optimization of operations.

4. Smart factory: With the help of intelligent workshop layout and ERP information management system, it will bring innovation to traditional production methods to the maximum. The database of the information management system can be interfaced with various external information systems through the gateway, and the workshop can be connected to the ERP system to query the production status of the workshop to realize the efficient configuration of the enterprise resources. With the SMS platform and mail platform, the information management platform can be used by the administrator. Real-time reporting of equipment failures, production schedules, and other information.

Previous:How to integrate industrial robots with CNC machine tools?

next:Hardware accessories painting robot spraying equipment