PRODUCT CATEGORIES

CONTACT US

DANBACH ROBOT JIANGXI.INC. Phone:0086-18801818975Tel:0086-0791-88133135

Fax:0086-0791-88221576

E-mail:info@dbhrobot.com

Address:Nanchang High - tech Zone Innovation No. 811

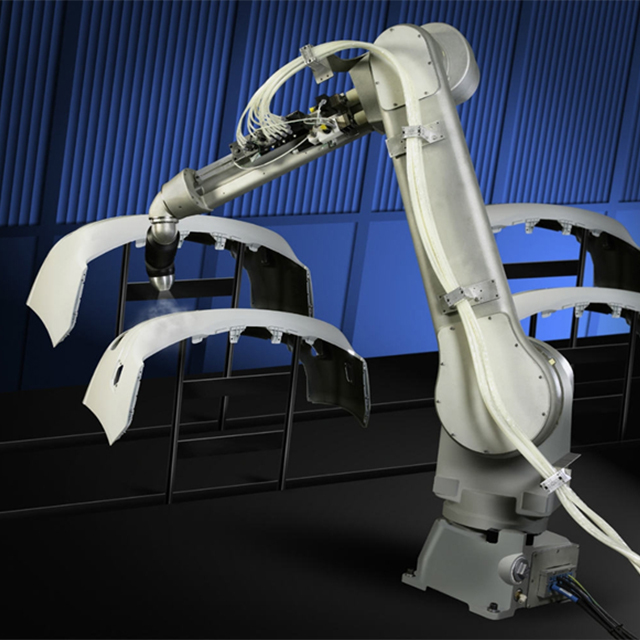

Danbach 6 axis robot for automotive assembly industry

DANBACH ROBOT

The assembly robot is the core equipment of the flexible automated assembly system and consists of a robot manipulator, a controller, an end effector and a sensor system. The types of robots include horizontal joints, rectangular coordinates, multi-articulations, and cylindrical coordinates; controllers generally use multiple CPUs or multi-level computer systems to implement motion control and motion programming; and end-effectors accommodate different assembly targets. It is designed into various grippers and wrists, etc.; the sensing system is also used to obtain information on the interaction between the assembly robot and the environment and assembly objects.

The features of 6 axis Assembly robot :

1. Each assembly robot arm can be equipped with different tooling according to the process requirements to meet the diverse production requirements for multi-batch and small-batch production lines in the future. It requires only simple programming and tooling replacement to achieve rapid switching.

2. The robot's high accuracy and job stability can be used in lean industrial production processes.

3. Assembly force control. The use of smart force/torque motion technology for component assembly eliminates the risk of stuck parts and damage.

4. The visual function guides the robot to correctly identify and grab the workpiece and transfer it to the precise assembly position.

5. The input-output ratio of robots is high and the equipment recovery period is short.

Danbach Assembly robots are widely used in various fields of industrial production. For example, in the automotive assembly industry, manual assembly has basically been replaced by automated production lines, which saves labor costs, reduces labor intensity, improves assembly quality, and ensures assembly safety. With the continuous development and improvement of the function of the assembly robot and the further reduction of the cost of the assembly robot, it will play a more important role in more fields in the future.

Previous:Bidirectional Automatic Lurking AGV For Materials Handling

next:Advantages of Low payload 6 axis small industrial welding robotic arm