PRODUCT CATEGORIES

CONTACT US

DANBACH ROBOT JIANGXI.INC. Phone:0086-18801818975Tel:0086-0791-88133135

Fax:0086-0791-88221576

E-mail:info@dbhrobot.com

Address:Nanchang High - tech Zone Innovation No. 811

Factors affecting the metal painting robot process

DANBACH ROBOT

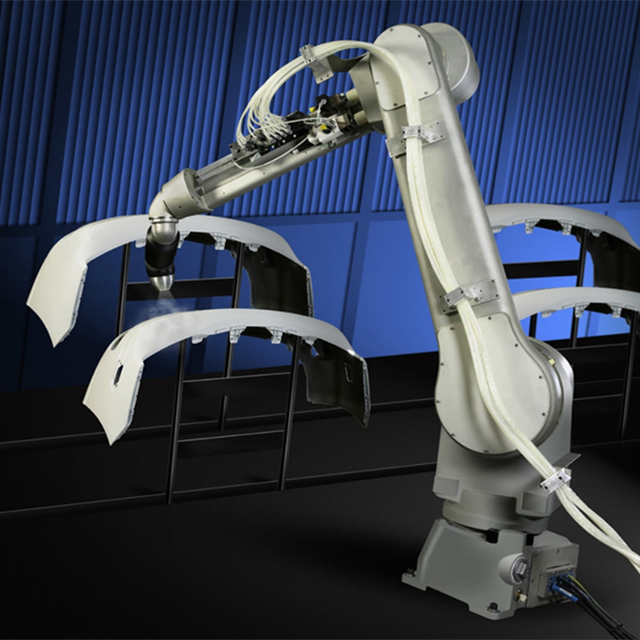

The spraying robot operation is very harmful to the human body. The workers in the post have high mobility and high labor costs. Therefore, many enterprises adopt the production mode of the machine to meet the needs of modern production. Spraying robots have the advantages of high precision and high performance. So, do you know the factors that affect the metal painting robot process?

What are the factors that affect the metal painting robot process? The corrosion of the painted metal is closely related to the corrosion resistance of the metal material itself. The metal used for painting is made of steel material, aluminum alloy, copper alloy or magnesium alloy. It is undoubtedly different in metal material, and the anti-corrosion performance of metal painting robot is not the same.

The difference in the surface state of the metal material is significantly different by the anti-corrosion and anti-corrosion protection effect of the coating. For example, the steel plate parts treated by sandblasting and the same grade steel plate parts that are naturally corroded are subjected to the same type of spray coating protection. Due to the adverse effects of corrosion, the corrosion rate of natural corroded steel plate parts is higher than that of the sandblasted steel plate parts. The corrosion protection effect is significantly lower than the latter.

Defects such as inclusions, microcracks, stress, etc. on the metal surface and the adsorption of moisture and active ions (Cl-, Br-, etc.) in the atmosphere will affect or even accelerate the corrosion of the painted metal of the paint robot.

Before the robot performs the spraying operation, the surface treatment process must be done to ensure the good adhesion of the paint coating protective layer and the base metal, and improve the anti-corrosion and anti-corrosion properties of the spray coating metal.

Previous:Defect analysis and solution of welding robot

next:AGV is used in many fields such as tobacco and clothing